The humble battery system: it’s used in all walks of life, but rarely do we give it a second thought. On this page, we’re going to be taking a closer look at battery systems, telling you exactly what they are and what their components are. And we know what we’re talking about, as we’ve been a leading name in the battery industry for decades!

Table of Contents:

Key Takeaways:

- Integrated Components: A battery system comprises cells, a BMS, connectors, and housing, all working together to ensure efficient energy storage and discharge.

- Safety and Performance: The BMS plays a vital role in monitoring and managing the battery’s health, ensuring safe and optimal performance.

- Wide Applications: Battery systems are essential in various fields, from personal electronics to industrial machinery and renewable energy solutions.

What is The Battery System?

So, let’s jump in and take a look at what exactly a battery system is. In its simplest terms, a battery system is a combination of many components, all of which work together to create an effective place for energy to be stored and discharged.

Unlike a single battery cell, a complete battery system is designed as an integrated solution, where electrical, mechanical, and electronic elements are carefully matched to ensure stable performance under real-world operating conditions.

A properly engineered battery system is not only responsible for storing energy, but also for controlling how that energy is delivered, protected, and monitored throughout its entire lifecycle.

You’ll find several key components in a battery system, and we’ve listed them below.

Battery cells

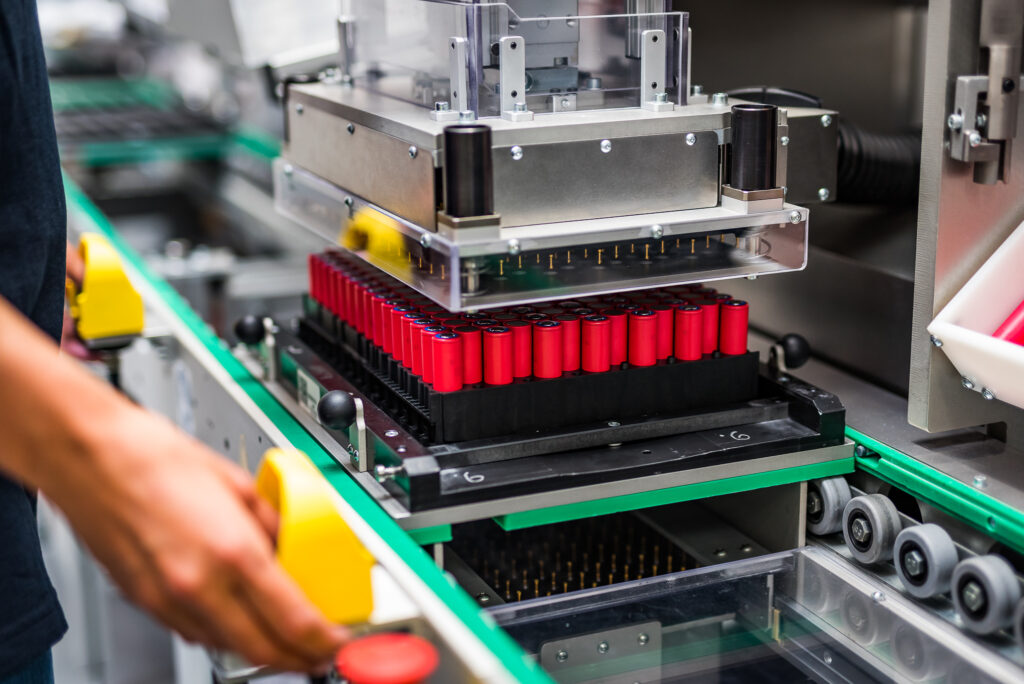

Cells. Battery cells store electrical energy in a chemical form, typically as lithium-ion or lead-acid, although other versions are also available. A battery system might just have a single cell, or it could have several cells linked together in series, to increase performance.

Cells form the foundation of every battery system, and their chemistry, capacity, and configuration directly determine energy density, voltage, and discharge characteristics.

One of the biggest questions to answer when designing a battery is which type of cells should be used? The answer depends on the intended application and specific requirements. For example, lithium-ion batteries are regularly used in portable electronics, as they have high energy density and performance.

In contrast, applications requiring high durability or lower cost may still rely on alternative chemistries. Selecting the right cell type is therefore a strategic decision that balances performance, safety, cost, and longevity.

Battery management system

Battery management system (BMS). The BMS monitors and controls the charging and discharging of the batteries, ensuring performance, safety, and longevity. Often, the BMS can communicate with the device using the battery for optimal effectiveness.

The BMS acts as the control centre of the battery system, continuously analysing data such as voltage, current, temperature, and state of charge. Based on this data, it can make real-time decisions to protect the battery and optimise its operation.

Not all batteries have built in BMS – for example, batteries used in small electronic devices often don’t have one. But a BMS is recommended in many situations. There are many to choose from, and the best way to choose which to use for your application is by liaising with a knowledgeable expert – such as the people here at EMBS.

In high-energy or mission-critical applications, the absence of a BMS can significantly increase the risk of failure, reduced lifespan, or safety incidents.

Cell connectors

Cell connectors: In order to work in unison, each cell needs to be connected to the others. This is done using cell connectors.

The quality and design of cell connectors have a direct impact on electrical resistance, thermal behaviour, and overall system reliability. Poor connections can lead to energy losses, uneven cell loading, or local overheating.

There are three main ways in which cells can be connected: gap junctions, tight junctions, and desmosomes. Each type has a different purpose. As with the BMS, our experts can tell you which cell connector your battery system needs.

Choosing the correct connection method is essential, especially in systems exposed to vibration, high currents, or frequent charge and discharge cycles.

Cell holders and housing

Cell holders and housing. Cells need to be held in place properly to ensure maximum durability and performance. Housing comes in many forms and can often be customised to fit perfectly with the intended application.

Beyond mechanical protection, housing also plays a role in thermal management, insulation, and environmental resistance, such as protection against dust, moisture, or chemical exposure.

Well-designed housing improves safety, simplifies maintenance, and allows battery systems to be seamlessly integrated into larger devices or installations.

Battery system functions and applications

Battery systems are an integral part of the world and will only continue developing as companies pour money into research and development. And EMBS is at the forefront of this push, aiming to improve the efficiency, capacity, safety, and environmental impact of battery systems.

From consumer electronics and power tools to electric vehicles, industrial automation, and renewable energy storage, battery systems enable mobility, flexibility, and decarbonisation across industries.

As energy demands grow and sustainability becomes a priority, advanced battery systems will play a central role in shaping future technologies and infrastructure.

Should you desire further information, kindly contact our specialist.

FAQ:

What is a battery system?

A battery system is a combination of various components that work together to store and discharge electrical energy effectively. It typically includes battery cells, a battery management system (BMS), cell connectors, and housing. These elements collaborate to ensure the battery operates safely and efficiently.

What components make up a battery system?

Key components of a battery system include:

Battery Cells: Store electrical energy in a chemical form, commonly using lithium-ion or lead-acid technologies.

Battery Management System (BMS): Monitors and controls the charging and discharging processes, ensuring performance, safety, and longevity.

Cell Connectors: Link individual cells together to form a complete battery pack.

Cell Holders and Housing: Secure the cells in place, providing structural integrity and protection.

Why is a Battery Management System (BMS) important?

The BMS is crucial for:

– Monitoring the voltage, current, and temperature of each cell.

– Balancing the charge across cells to prevent overcharging or deep discharging.

– Protecting the battery from unsafe operating conditions.

– Communicating with the device to optimize performance and safety.

What are the applications of battery systems?

Battery systems are integral to various industries and applications, including:

E-Mobility: Powering electric vehicles and bicycles.

Power Tools: Providing cordless operation for tools.

Healthcare: Supplying energy to medical devices like defibrillators and drug pumps.

Energy Storage: Storing energy for later use, especially in renewable energy systems.

Drones: Enabling flight and operation of unmanned aerial vehicles.

Sources

Rahn, C. D., & Wang, C. Y. (2013). Battery systems engineering. John Wiley & Sons.

Atcitty, S., Neely, J., Ingersoll, D., Akhil, A., & Waldrip, K. (2013). Battery energy storage system. In Power Electronics for Renewable and Distributed Energy Systems: A Sourcebook of Topologies, Control and Integration (pp. 333-366). London: Springer London.

Horiba, T. (2014). Lithium-ion battery systems. Proceedings of the IEEE, 102(6), 939-950. http://ael.chungbuk.ac.kr/lectures/lecture_notes/battery-and-energy-storage/Lithium-Ion_Battery_Systems.pdf

Plett, G. L. (2015). Battery management systems, Volume I: Battery modeling. Artech House.

About the Author

EMBS

Leading manufacturer of advanced battery systems with a market presence of over 25 years. We specialise in rechargeable lithium-ion batteries, producing a wide range of systems with varying power and capacity.