01

Tools and equipment

Designing and making prototypes requires the appropriate tools, knowledge and experience. The engineering competence of our specialists and our 3D modelling software significantly reduce the design and manufacturing time of prototype parts, as well as the tools used in FDM and SLS production processes.

02

Testing

and programming

Offering products of the highest quality would not be possible without proper testing at various stages of the production processes. We perform tests to the highest standards on the production line or in our laboratories. We carry out the design and programming of test sequences using LabVieW software along with engineering know-how and competence, developed and refined in our internal Test & Validation team. We provide a competitive advantage by operating the equipment autonomously and responding to changing customer needs – throughout the product lifecycle.

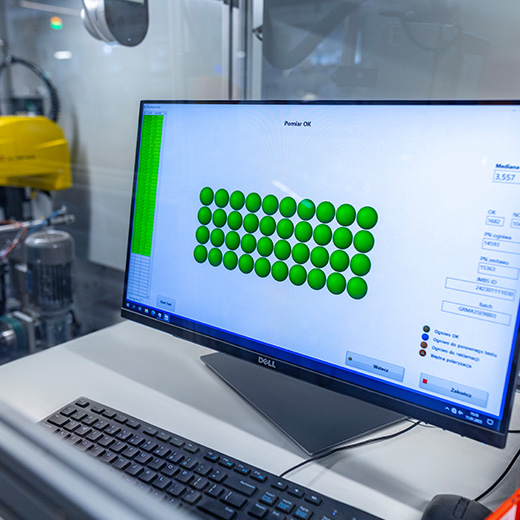

Testing – Pre-test

A pre-test is one of the first stages of testing, which involves testing individual cells using three algorithms (min-max, median, average value). This ensures the best possible match between all the individual cells that a battery is constructed from.

Parameters

| 3 types of algorithms (min-max, median, average value) |

| Actual view of the cell |

| Acoustic fault indication |

| Polarisation error and battery voltage error are separated |

| Possibility of visualisation of any battery shape |

| Data logging to CSV files, possible connection to a database |

| Standard resolution every 1 mV |

| Push-button or automatic triggering |

| Communication via Ethernet |

| Internal resistance measurement of an ACIR cell |

Testing – Midtest

Midtest is the testing of cell modules at an intermediate stage of the process. We perform this type of test to ensure that the blocks that make up the battery are correctly matched.

Parameters

| Actual view of the cell |

| Acoustic fault indication |

| Separation of the polarisation error from the battery voltage error |

| Possibility of visualisation of any battery shape |

| Recording of data to CSV files, possible connection to a database |

| Standard resolution every 1 mV |

| Communication via Ethernet |

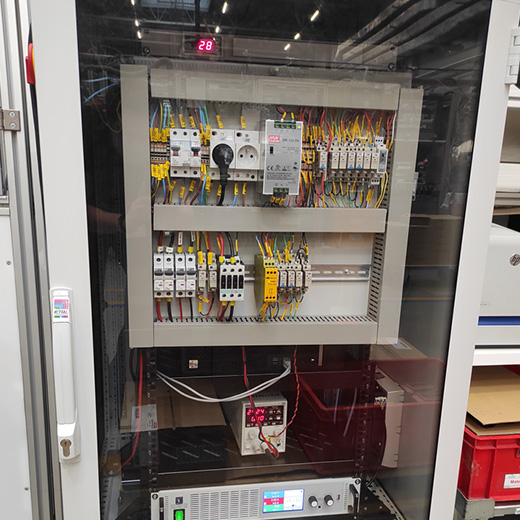

Testing – EOL test

We carry out the EOL test in the last phase of the battery assembly process involving parameter verification. The test is carried out using an adaptor designed to check the user’s socket and confirm the correct operation of the battery.

Parameters

| Communication – CAN, UART |

| Load tests up to 200 A |

| Charging tests up to 60 A |

| Short circuit tests |

| LED monitoring |

| Button test |

| Printing labels and verification by scanning the QR code |

| Data recording in CSV file |

| Dedicated adapter – can be exchanged for another battery model |

PCB programming

We use a dedicated adapter to ensure up-to-date programming on the PCB. The programming adaptor can also act as a control for the PCB-mounted button and verify correct operation before installation in the battery.

Main device parameters

| Button position control with an accuracy of 10 µm |

| PCB test and programming |

| Data recording in CSV file |

| Automatic temperature-dependent adjustment |

Testing – the root cause analysis of battery problems

Testing is a fundamental process that allows us to ensure that the battery is working properly and to eliminate possible faults. When battery problems occur, we provide support in identifying and resolving issues by performing

- electrical tests checking all suspect components,

- microscopic analyses,

- laboratory testing.

03

ESD

ESD (Electro-Static Discharge) protection is a system that ensures the safety of electronic components sensitive to electrostatic discharge. Charge flow and high voltage can damage components at any stage of production, transport or use. Proper ESD protection of products is a guarantee of their high quality and proper functioning.

EPA zone – A production space that is safe in terms of the presence of objects and ESD activity is referred to as an EPA (Electro-Static Protection Area) zone. This zone is marked with restriction strips and information labels. The EPA zone is tested for compliance and approved with a certificate.

ESD coordinator

We have a competent and experienced person on our team who is responsible for ESD protection matters. This person’s responsibilities include maintaining a list of all equipment and objects approved for ESD protection, as well as periodic measurements and procedures for safe employee behaviour. The ESD coordinator acts as an auditor at inspection audits and also ensures that ESD conditions are fulfilled, which are defined by the standards developed by the International European Commission EN 61340-5-1:2009 and EN 61340-5-2:2002.

ESD protection for staff

On a regular basis, we train our staff regarding ESD safety. The most important element in protecting staff is the earthing of the workplace. Workplace safety is ensured by specially adapted workstations with double-layered table mats and wristbands that dissipate charges from the body. The team members present in the EPA area wears ESD workwear, gloves and special footwear or protectors with a conductive shoe strap.

04

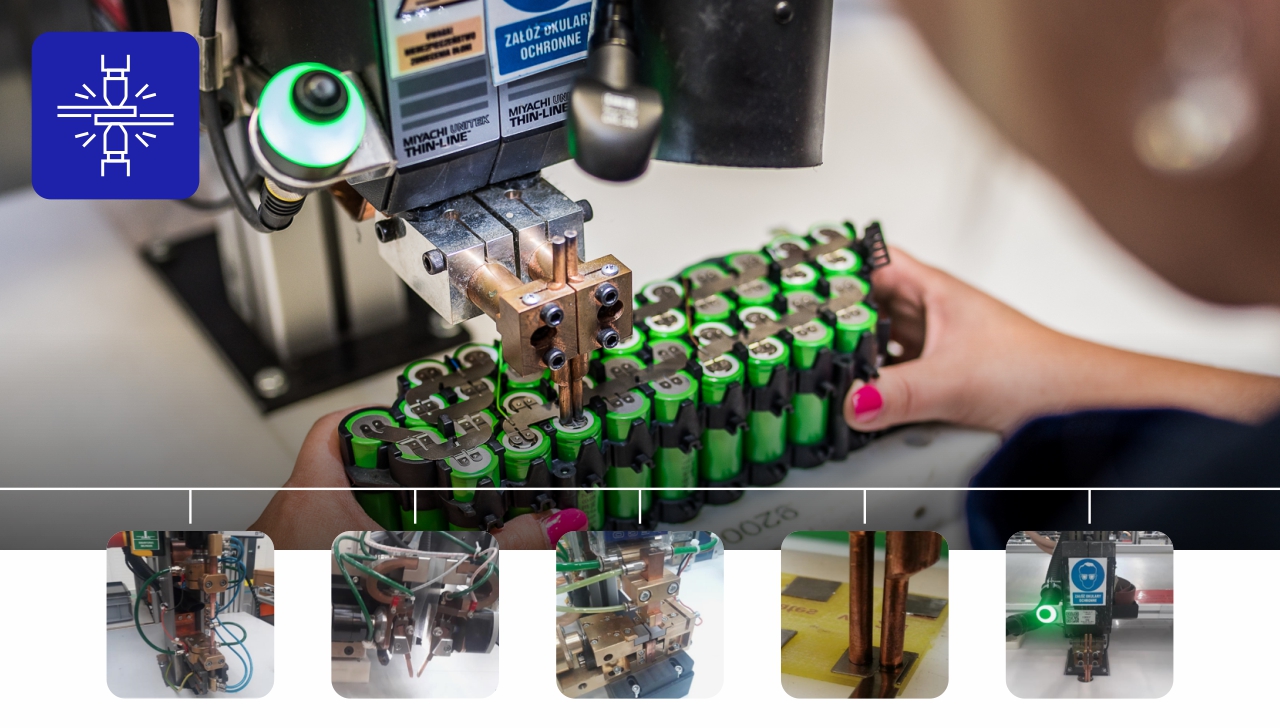

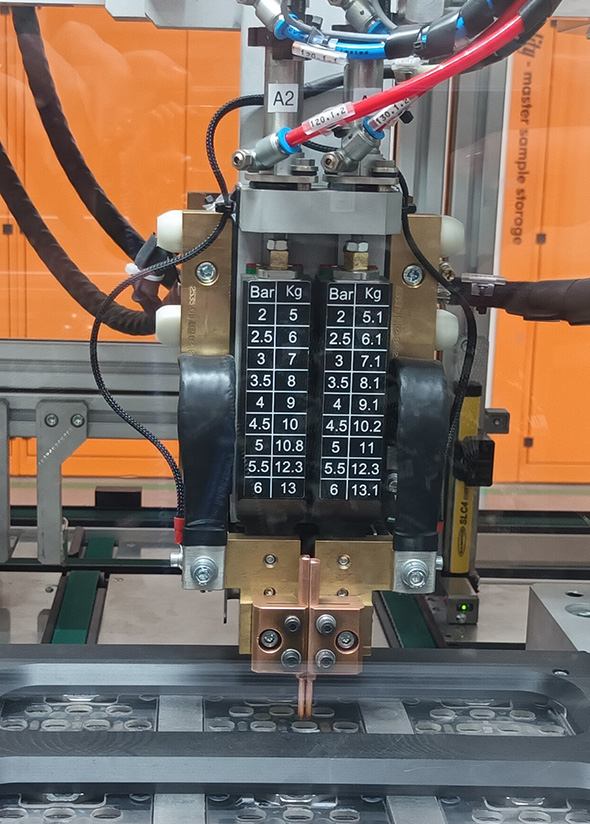

Welding

Welding is a very important process with a direct impact on battery quality. It defines the electrical parameters, which are one of the basic properties of the battery. The joining process is in several stages and begins with the selection of welded materials, the definition of the type of connections and the definition of the joining technology used.

Tests and validation of the connections must confirm a stable and durable joining process that has been selected to provide connections according to customer requirements.

In a battery, there may be several to dozens of connections made using resistance welding technology.

We develop the welding process parameters individually for each connection in accordance with accepted standards and procedures.

For resistance welding, the selection of equipment, electrodes, the establishment of process parameters and control parameters in the process are very important.

Due to the use of advanced resistance welding equipment, we can check the established control parameters (e.g., voltage, current, time) in real-time and stop the process if necessary.

We assess the quality of welded connections on the basis of destructive and non-destructive tests (e.g., breaking test, hardness test, metallography, X-Ray).

Welding types

Resistance welding

- spot welding

- compact welding

- gap welding

- step welding

- pincer welding

Welding – validation and capability testing

An important step in the welding process is validation and capability testing. We perform these tests through the following:

- analysis of the welding specifications

- welding tests (defined material and electrode shape)

- the setting of welding process parameters (also MIN and MAX values)

- validation/SPC

- X-RAY analysis and/or metallography

- documentation of welding process parameters

05

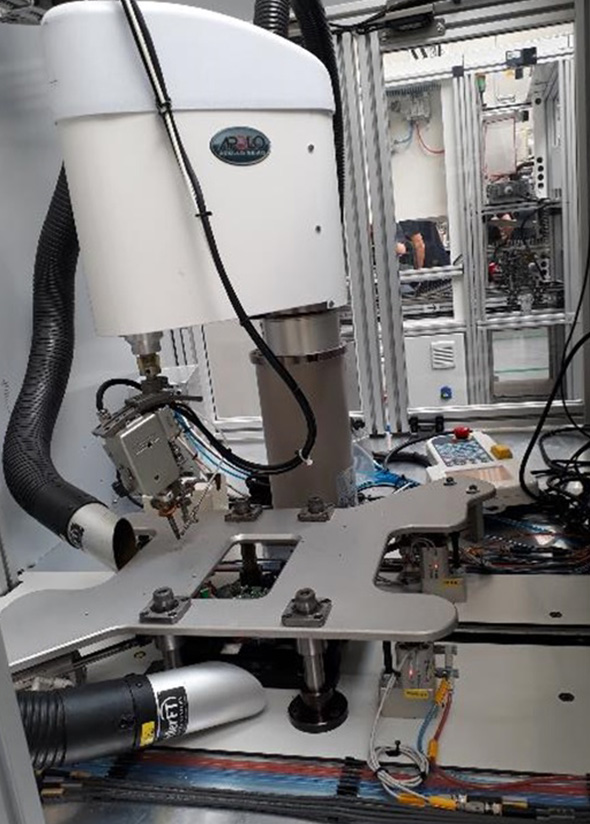

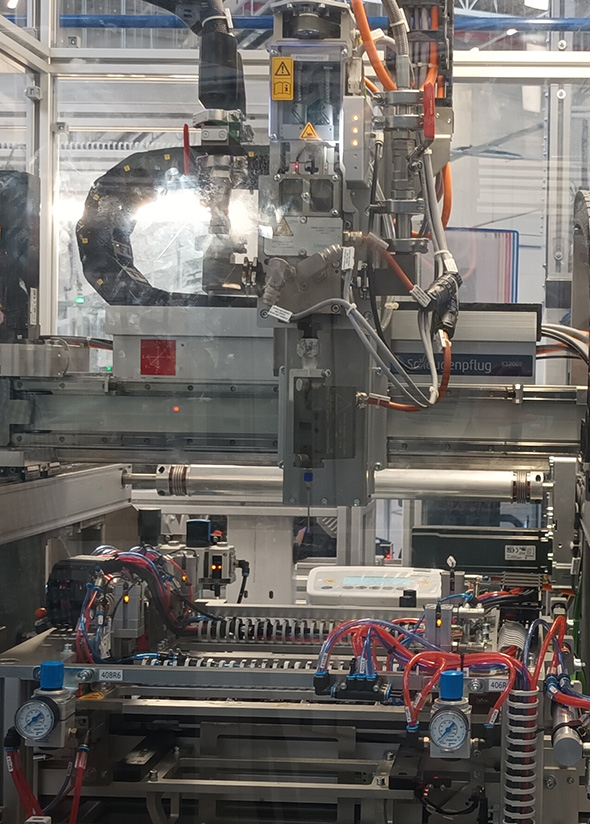

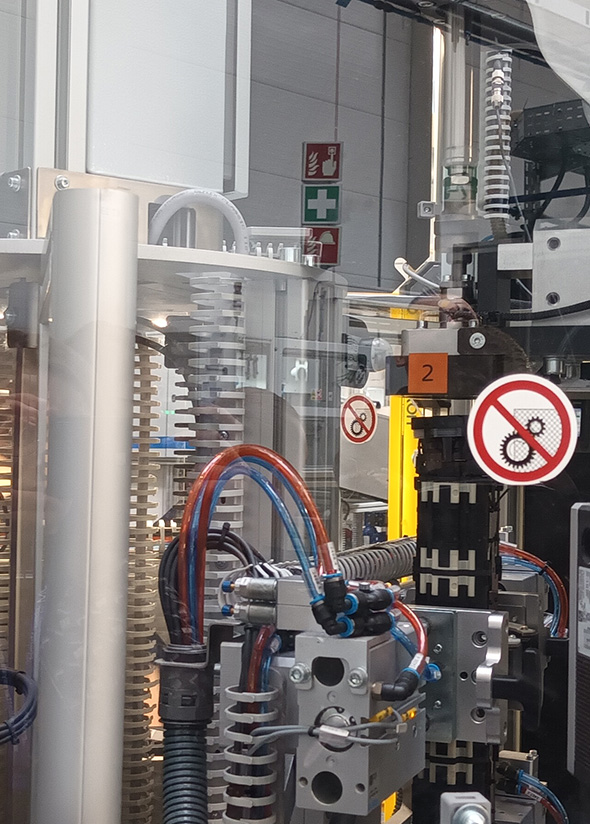

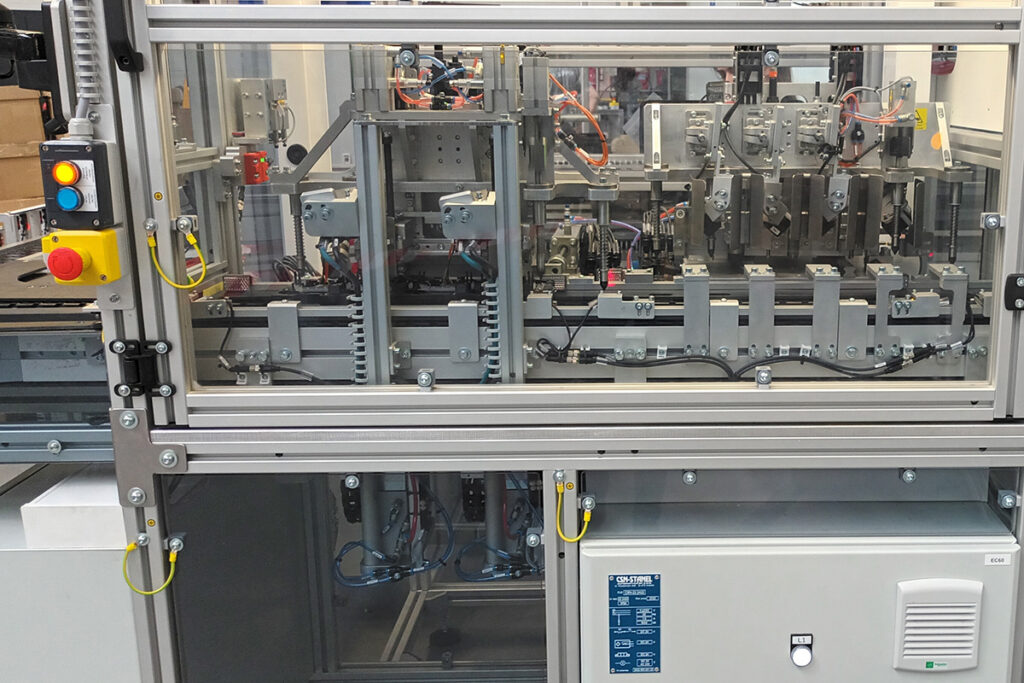

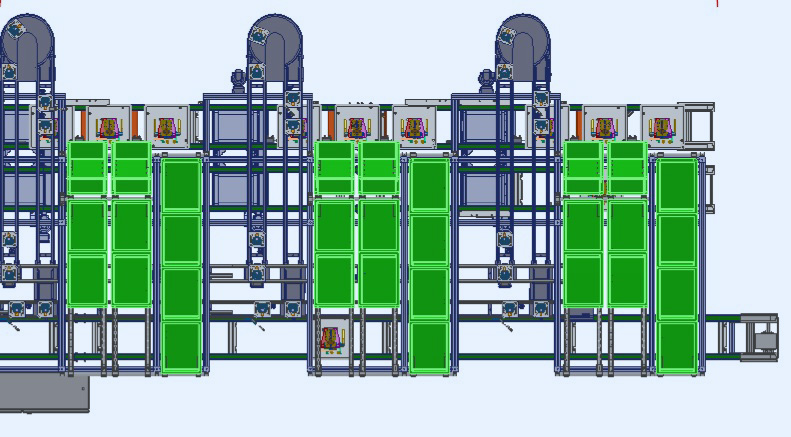

Automation – cell test and assembly

The automation of the cell test and assembly process consists of the following steps:

- measuring the voltage and polarity of each cell,

- comparison of voltage between cells,

- placement of cells in cell holders by robots.

Automation – the soldering process

Soldering is a very common process during battery production, which can be done in a fully automated form. The process of automated soldering is based on a system using SCARA robots, a soldering head, a tin dispensing system and a temperature controller. The use of this solution significantly increases safety, productivity, precision and the repeatability and quality of the soldered joints. The system used by SCARA robots allows for:

- performing a repeatable process in terms of ensuring the correct solder joint,

- control of process parameters,

- reducing the risk of “cold solder”.

Automation – screwing/twisting process

Automation of the twisting process in battery production allows for increased productivity, control of the sequence, setting of the twisting strategy and monitoring and recording of the twisting process parameters (e.g., torque, angle, sequence).

The automated twisting system includes:

- an advanced driver/controller

- spanner with strain gauge or current sensor

- part feeder

Automation – Welding

The automated welding process is mainly about

- precise product positioning,

- automated control of welding parameters and NOK detection,

- high efficiency of the welding process.

Pressing

The automated pressing process is:

- control of process parameters ( contact force and displacement),

- NOK detection.

Membrane application

Membrane application consists of the following steps:

- automated membrane application,

- integrated air flow measurement,

- NOK detection.

06

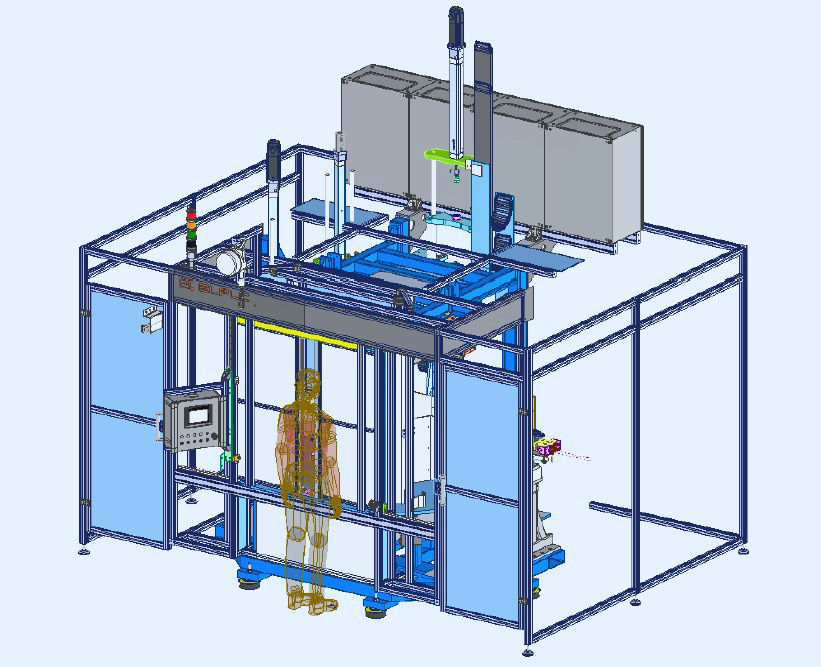

Dosing and potting

The purpose of the dosing or potting process is to increase the safety and service life of critical components (e.g., electronics) and to ensure proper sealing.

2-Component potting and dispensing

2-Component potting and dispensing (including the dispensing of thermal paste) are carried out using an automatic station incorporating an advanced component feeding and mixing system, as well as a head mounted on a Cartesian robot. This allows the aforementioned processes to be very precise and repeatable.

07

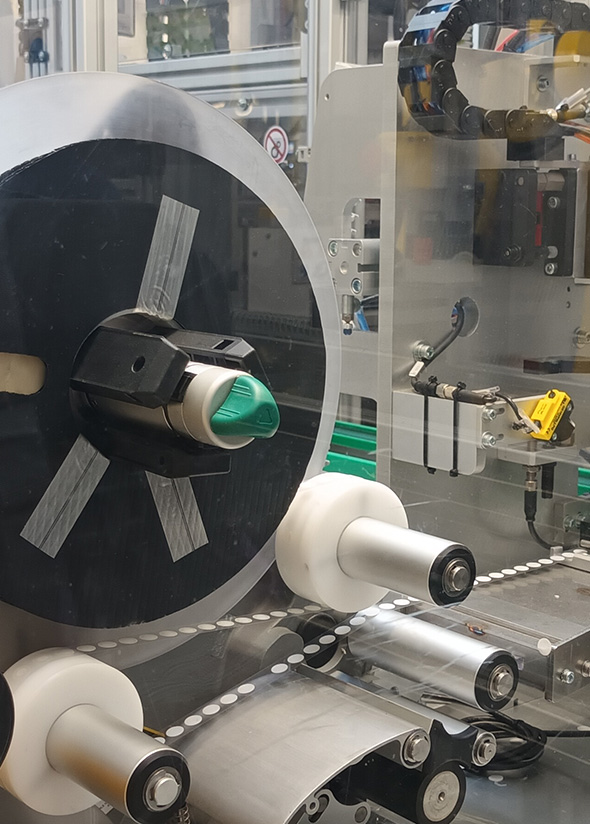

Product labelling

The final stage in the production process is product marking. We perform the entire marking process in compliance with current standards and legal requirements.

We mark products using the following techniques:

- laser marking,

- pad printing,

- stick-on labels printed using thermo-transfer technology.

Laser marking is an automated process that enables very fast, reproducible marking of data transmitted from other devices, for example the serial number assigned by the EoL tester.

Pad printing is a technique used to apply, among other things, the manufacturer’s description and logo to the product. The great advantage of pad printing is that it can be printed on any surface. A smooth silicon pad (printing pad) with high chemical resistance is used to transfer the ink from the plate to the object.

08

Data collection

and part identification

Our traceability system allows the tracing of all components, the technological parameters used in the process and the assignment of control data, if defined. Traceability of parts in production is achieved by supplying parts in labelled containers using barcodes, QR or DMC.

An essential part of the production process is the identification of parts throughout each stage and the relevant data assigned to them. This is made possible by the RFID technology installed. The assigned data allows us to accurately analyse and optimise processes and times.

09

Start-up of the machine/production line

Start-up of a machine/production line requires adequate preparation. The entire process is carried out in accordance with developed procedures and legal and safety requirements. The launching process includes individual stages, which consist of:

Preparation of machine specifications

- It takes place on the basis of a developed process

- Covers all customer requirements

- Covers all general EMBS requirements and automation standards

Acceptance of 3D model

- It is at this stage that most design errors and conceptual flaws are discovered

Collection of the machine/line from the supplier

- Verification of security systems

- First tests and trial production

- Verification of compliance with requirements

Final acceptance

- Verification at Run@Rate