The average battery system has several components, including cells and housing. Many also have a battery management system (BMS). But what is the battery management system?

Table of Contents:

Key Takeaways

- Essential for Battery Health: A BMS is vital for maintaining the efficiency and safety of battery systems.

- Prevents Damage: It safeguards against overcharging, over-discharging, and temperature extremes.

- Improves Longevity: By balancing cells and monitoring performance, a BMS extends the overall lifespan of the battery.

- Facilitates Communication: Enables integration with other systems through data transmission protocols.

- Adapts to Advancements: As battery technologies evolve, BMS features are expected to include predictive maintenance and enhanced safety measures.

What Exactly is a BMS?

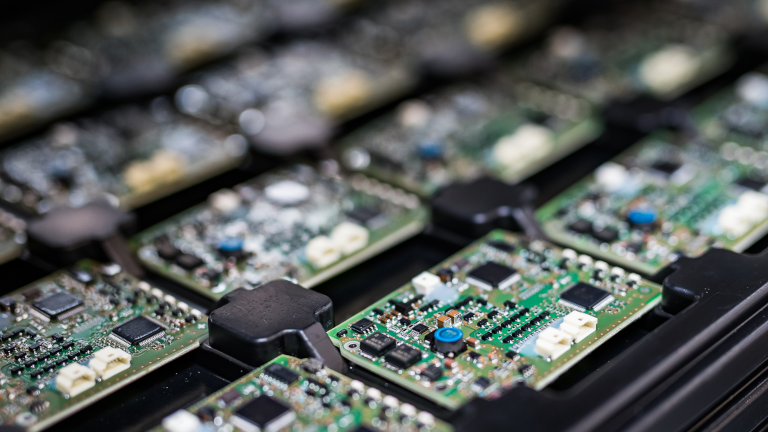

A Battery Management System is an electronic control unit that monitors and manages the performance of battery packs or individual cells. This not only helps to achieve maximum efficiency, lifespan, and performance, but also serves an important safety role.

In modern battery-powered systems, a BMS acts as the “brain” of the battery, continuously collecting and analysing data to ensure optimal operation under varying load and environmental conditions. Without a BMS, high-capacity batteries would be far more prone to degradation, instability, and safety incidents.

The role of a BMS becomes increasingly critical as battery packs grow in size, complexity, and energy density, where even small irregularities at cell level can have serious consequences.

Key Functions of a Battery Management System

So, what are some of the most important jobs carried out by a BMS? Take a look below…

- Cell monitoring. A BMS constantly monitors the voltage, current, and temperature of each cell within a battery pack. This allows discrepancies between different cells to be found and facilitates balanced charging of cells. Continuous cell-level monitoring ensures that potential issues such as abnormal voltage drops or temperature spikes are detected early, before they can lead to irreversible damage or safety hazards.

- SoC estimation. State of Charge (SoC) is essentially how much energy is left in the battery. The BMS monitors this and informs the user of the data. This can then be used, for example, to estimate the range left in a battery-operated vehicle. Accurate SoC estimation is crucial for user confidence and system planning, particularly in applications where uninterrupted operation is essential. Advanced algorithms allow the BMS to deliver reliable estimates even under fluctuating load conditions.

- Balancing cells. Over time, variations in performance can develop in different cells within a multi-cell battery back. A BMS will balance these cells by redistributing charge between them, extending battery life. Cell balancing prevents individual cells from being overstressed and ensures that the entire battery pack ages evenly, which directly contributes to improved reliability and lower maintenance costs over time.

- Overcharge and over-discharge protection. A critical function of the BMS is to prevent overcharging and over-discharging of cells. By enforcing safe voltage limits, the BMS protects cells from chemical degradation, capacity loss, and potential thermal runaway, which is especially important in high-energy lithium-ion systems.

- Temperature management. The BMS ensures the battery operates within a safe range of temperatures. If the battery gets too hot or cold, a BMS can initiate cooling or heating systems to maintain optimal temperature conditions. Effective thermal management not only improves safety but also stabilises performance, as battery efficiency and lifespan are highly sensitive to temperature fluctuations.

- Communication. A BMS can send data via CANBUS or other systems with information on the state of charge, errors, and other data required for diagnostics. This communication capability allows seamless integration with vehicles, industrial equipment, or energy management systems, enabling remote monitoring, fault detection, and predictive maintenance strategies.

The Future Importance of Battery Management Systems

The significance of Battery Management System will only increase as battery technology advances. With the adoption of advanced materials and chemistries, BMS will have to adapt to meet new challenges. Innovations could include predictive maintenance, enhanced communication abilities, and advanced safety features. At EMBS, we’ll be at the forefront of these improvements. If you would like to learn more, please reach out to our specialist.

Future BMS solutions are expected to incorporate machine learning, predictive analytics, and enhanced safety logic, allowing systems to anticipate failures before they occur and optimise performance dynamically.

As batteries become a cornerstone of electrification across industries, the BMS will play a central role in ensuring reliability, scalability, and regulatory compliance.

At EMBS, we’ll be at the forefront of these improvements. If you would like to learn more, please reach out to our specialist.

FAQ

What is a Battery Management System (BMS)?

A Battery Management System (BMS) is an electronic control unit that monitors and manages the performance of battery packs or individual cells. It ensures maximum efficiency, lifespan, and performance while serving a crucial safety role.

What are the key functions of a BMS?

A BMS performs several critical functions:

Cell Monitoring: Continuously tracks the voltage, current, and temperature of each cell within a battery pack.

State of Charge (SoC) Estimation: Determines the remaining energy in the battery, aiding in estimating the remaining runtime.

Cell Balancing: Redistributes charge between cells to ensure uniform performance and extend battery life.

Overcharge and Over-discharge Protection: Prevents cells from operating outside safe voltage limits, protecting against potential damage.

Temperature Management: Activates cooling or heating systems to maintain optimal operating temperatures.

Communication: Transmits data via protocols like CANBUS for diagnostics and system integration.

Why is a BMS important?

A BMS is vital for maintaining battery health by preventing damage from overcharging, over-discharging, and temperature extremes. It enhances battery longevity through cell balancing and performance monitoring. Additionally, it facilitates communication with other systems, enabling predictive maintenance and integration with advanced technologies.

How does a BMS contribute to battery safety?

By monitoring critical parameters such as voltage, current, and temperature, a BMS can detect unsafe conditions and take corrective actions. For instance, it can disconnect the battery during overcurrent situations or initiate cooling mechanisms during overheating, thereby preventing potential hazards.

In which applications is a BMS used?

BMS is employed in various applications, including:

Electric Vehicles (EVs): Managing battery performance and safety.

Renewable Energy Storage Systems: Ensuring efficient energy storage and retrieval.

Portable Electronics: Maintaining battery health in devices like smartphones and laptops.

Power Tools: Optimizing battery usage and longevity.

Medical Devices: Providing reliable power for critical equipment.

Sources

Zhu, F., Liu, G., Tao, C., Wang, K., & Jiang, K. (2017). Battery management system for Li‐ion battery. The Journal of Engineering, 2017(13), 1437-1440.

Li, S., & Zhang, C. (2009, March). Study on battery management system and lithium-ion battery. In 2009 International Conference on Computer and Automation Engineering (pp. 218-222). IEEE.

Lelie, M., Braun, T., Knips, M., Nordmann, H., Ringbeck, F., Zappen, H., & Sauer, D. U. (2018). Battery management system hardware concepts: An overview. Applied Sciences, 8(4), 534.

Jossen, A., Späth, V., Döring, H., & Garche, J. (1999). Reliable battery operation—a challenge for the battery management system. Journal of Power Sources, 84(2), 283-286.

About the Author

EMBS

Leading manufacturer of advanced battery systems with a market presence of over 25 years. We specialise in rechargeable lithium-ion batteries, producing a wide range of systems with varying power and capacity.